Products

Overview

Essential details

Size : 117.5*149/152.5*26

Brand Name : SNAK

Product Name : 46305 Wheel Hub Oil Seal

Certificate :ISO9001/TS16949

Type : Front Wheel Oil Seal

Pressure tolerance : 0-1000 fpm

Hardness : 70 Shore

Place of Origin : Hebei, China

Model Number : 46305

Color : Customers Required

Features : High Temperature Resistance

Material type : NBR

OEM : Provided

Packing : Plastic Bags +Carton

Packaging & delivery

Supply Ability:1000000 Piece/Pieces per Week

Port:China Port

Package Type : cartons packing Delivery Detail Within 15 days

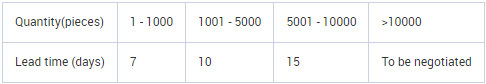

Lead time :

SNAK Factory Hot Sale 117.5*149/152.5*26 T4625 Trailer Axle Hub Seal National 370025A CR 46300 46304 46305 Wheel Hub Oil Seal

*Wheel seal

The wheel seal is often part of a wheel bearing assembly. It serves two important purposes:

1. The wheel bearing uses grease as a lubricant. The bearings needs to be constantly lubricated as the wheel turns. The wheel seal keeps the grease inside the wheel bearing assembly.

2. The wheel seal keeps all water, dirt, and other impurities out of the wheel bearing assembly.

The wheel seal plays a large role in your wheel bearing’s longevity. It’s a large rubber and metal seal that is sometimes located

in the hub. Depending on the design of the wheel bearing and hub, the wheel seal is installed either:

*Directly into the hub

*Onto the spindle

t’s always smart to replace the wheel seal when replacing the rear axle wheel bearings. A seal is a cheap part that protects expensive parts. If you notice the wheel seal has gone bad, replace it as soon as possible, and you may not have to replace the bearing.

*Reason for leaking

01. quality of seal, cheap aftermarket copies of OEM parts which are poorly made

02. seal not put in straight causing rapid wear of seal lip and oil egress due to wipe over

03. new seal put in on edge of wear groove on crank causing flipping of seal in and out ofgroove

04. poor fitting of seal causing damage to lip or dislodging of spiral supporting spring

05. poor finish on shaft surface causing erosion of seal 06.excessive crankcase pressure due to poor installation of/lack of PCV system causing leak of oil/blow out of seal / dislodging of seal.

Tens of thousands of specifications are available from stock. For more models and specifications,

please consult customer service

Keywords:

Featured Products

11

11 +86-18733900528

+86-18733900528  13930962126@cc.cc

13930962126@cc.cc